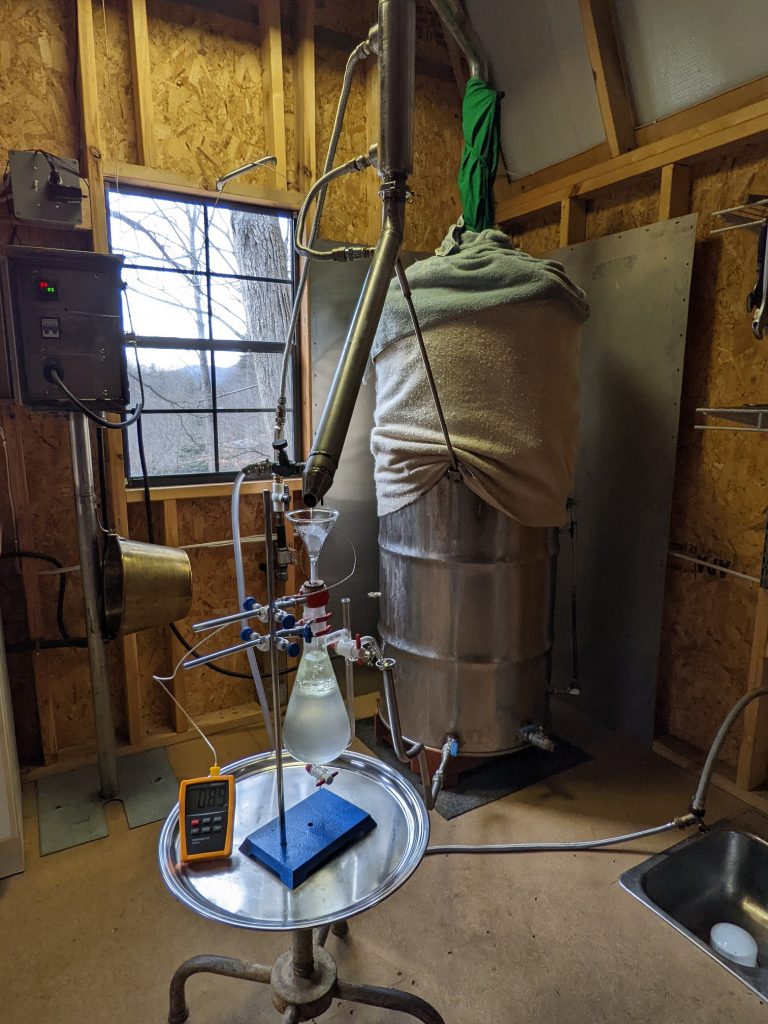

80 Gallon Electric Essential Oil Still

Blue Ridge Aromatics’ first and trusty production still is ready to find a new home. Originally built in 2015 for indoor use, this stainless steel (recycled/upcycled) essential oil still has been dialed-in to a reliable and efficient steam distillation machine. It has a plant material capacity of about 45 gallons and comes with a digital controller for semi-automated distillation. Turn-key; all you need is a 220/240-volt 30 amp outlet (like for a dryer or stove) and around 25 gallons per hour of cooling water. Can produce up to ~16 ounces of pure essential oil per batch (oil yields vary widely depending on species). $10,000 If you would like to purchase or discuss this still, please contact us directly.

Description

80 Gallon Electric Essential Oil Steam Distillation Machine – $10,000

Dubbed “Dante” by popular vote, this essential oil still has been used to produce dozens of liters of essential oil over the past 8 years. In 3,600 hours of use and 334 unique batches, I have refined and upgraded this still to be a reliable, clean, efficient and safe workhorse.

The total volume of the still is 80 gallons but the material baskets hold about 45 gallons. The remaining 35 gallons holds the boiler water and provides air/steam space between the boiling water and the plant material. This translates to capacities of around 50 lbs of herbs (like mint or lavender) or 80-100 lbs of denser plant material (like mulched pine branches).

Dante is electrically powered (240/220v, 30 Amps) and nearly silent with a digital controller for some process automation. Being electric, Dante can be used indoors with no risk of gas leaks or carbon-monoxide poisoning like a propane still would have. That said, exhaust ventilation or fresh air supply is important as the essential oil vapors can get quite intense in a closed space.

Dante was made (mostly) from recycled/upcycled stainless steel materials. The main body of the still started life as food-grade barrels holding Cinnamon oil for a major Southern soft-drink manufacturer. The plumbing components were sourced from waste brewery manufacturing materials. The screen material for the baskets came from unused but damaged washing machine drums. This is why a still this good and of its size can be priced under $20k.

This essential oil still is a sort-of modular design. Here’s how it works:

- The lower section is the boiler. This holds the boiler water, the heating element and a drop-in ~15 gallon plant material basket. It has a sight gauge to check water level, a drain/fill valve with water hose connection and a hydrosol recirculation port (which may or may not be used depending on your need). Recirculating the hydrosol (cohobation) means the still can run for 24 hours or more without needing to add water. Without recirculating the hydrosol, the still can run for 6-8 hours.

- The upper section is a ~28 gallon plant material basket that clamps to the boiler. The domed lid clamps to this material basket. I made the material baskets removable/modular for easier handling and cleaning, however a rolling hoist is included with the still as the upper basket can weigh over 100 lbs after distillation.

- The steam/vapor plumbing directs the steam that has passed through the material baskets into the condenser. Oversized (2″) plumbing means that there is no chance of explosion from back-pressure. Convenient sanitary tri-clamps with PTFE seals hold the plumbing together so each piece can be removed without tools for effective cleaning.

- The primary condenser consists of 13 small tubes surrounded by a water jacket. The steam and vapor holding the extracted essential oils is pushed through the condenser’s inner tubes. Cool water flows through the water jacket, cooling the inner tubes; thus the vapor passing through those tubes is cooled and condensed back into a liquid. There is also a second condenser that further conditions the temperature of the still’s output (distillate) for fine-tuning. The temperature of the distillate plays a big role in how well essential oil separates from hydrosol/water.

- The included separatory funnel is a laboratory glass device that provides room and proper overflow conditions for the essential oil to separate from the distillate/hydrosol; allowing the pure oil to be readily collected/bottled.

- Dante was designed with ease of (indoor) use in mind with a few small compromises for a larger batch-capacity.

- Plant material is hand-loaded into the assembled and pre-heated still

- The boiler can be cleaned in-place with biodegradable dish soap and water (with a water-hose to outside or a floor drain). The heating element is easily removable for its (necessary) cleaning after each batch.

- The material baskets are too large to clean in a normal sink and, when full, a bit too heavy to be tossing around by hand (hence the included rolling hoist/crane). So the baskets can be cleaned outside or in a commercial-sized sink.

- These compromises are beneficial though as most stills this size are not indoor-friendly and have to be dumped out where they sit. Or a couple hundred lbs of wet (steamed) plant material has to be hoisted 4-5 feet up and moved with equipment.

- The electronic still controller automates some of the distillation process and provides a few safety benefits.

- In Mash mode, you can set a pre-heat temperature that allows for a quicker batch startup while not wasting energy/water from over-heating your warm-up.

- In Boil mode the still runs at full power to boiling and then throttles down to your preferred setting. I usually set the throttle power to 85% then turn it up as I dial in the cooling water flow.

- A timer starts at boiling and shuts off the still when the timer runs out. So once you come to understand the oil output timeline of the plant(s) you are working with, you can adjust the timer and further automate the process (and potentially save electricity).

- The controller has a built-in circuit breaker as well as fault-detection coded in. In other words, if something goes wrong the controller will kill power to the still rather than blindly keep sending power to a loose/corroded electrical connection or burnt-out heating element.

- Not all of the distillation process can be automated. The end goal (for optimal essential oil yield and separation) is to have distillate leaving the still around 100 F. Cooling water temperature, cooling water flow, ambient temperatures, the density of the plant material and the power level of the controller will all affect the temperature of the still’s output. So the first hour+ of the distillation will have you monitoring the distillate and adjusting cooling water flow and/or power level. Once a temperature/output stability is reached, the still can run on its own for hours.

Some questions you may have:

- Q: Why are you selling your production still?

- A: Blue Ridge Aromatics is ready for a bigger still. I have most of the parts and most of the design, but not the time or capital to complete a new (bigger) still. Proceeds from this sale will fund the time and materials to do so.

- Q: How much oil can I make with Dante?

- A: Realistically, that depends on your energy and persistence! My batches with Dante have ranged from a measly few ml of oil to about 500ml. You will need to find the plants available to you that yield well. I can provide some guidance on this subject (mainly Eastern USA climate). Additionally, harvesting, processing, loading, unloading and cleaning the still are all labor-intensive jobs. For many batches, the prep and cleanup far exceed the actual distillation time. So one can only make as much oil as they have the energy for.

- Starting an essential oil business with Dante: This is what I did. Using this still, and having found the plants that work for me, I am able to produce enough essential oil to sell small bottles of select species here on the website, at farmer’s markets and a limited number of retail stores.

- A: Realistically, that depends on your energy and persistence! My batches with Dante have ranged from a measly few ml of oil to about 500ml. You will need to find the plants available to you that yield well. I can provide some guidance on this subject (mainly Eastern USA climate). Additionally, harvesting, processing, loading, unloading and cleaning the still are all labor-intensive jobs. For many batches, the prep and cleanup far exceed the actual distillation time. So one can only make as much oil as they have the energy for.

- Q: Can the cooling water be re-circulated or well or municipal water?

- A: Re-circulated – The problem with cooling water re-circulation is that the cooling water will continually rise in temp, causing runaway distillate temps that, un-checked, will lead to losing oil as vapor. Perhaps a large reservoir such as a swimming pool could be used if you’d like to heat your pool with your still. It might not be a good idea for a pond with flora and fauna though.

- A: Well or municipal water: This is reasonable but batch costs will increase; either electrically for a well pump or in utilities costs for water/sewer. Expect to use around 20+ gallons per hour of ~65 F water. Note: the still controller can be dialed back to as slow as you want to go, reducing the need for cooling water.

- A: Note on using well or municipal water in the boiler. Cleaning the heating element is even more important with mineral-rich well water or chlorine/flouride-containing municipal water. If the element gets too dirty, it will self-destruct. For municipal water, it would be best to fill the still and let it sit overnight, uncovered, so it has time to evaporate the chemicals before loading your batch and running it.

- Q: Can I collect essential oil AND hydrosol with this still?

- A: Absolutely! The essential oil separator (essencier) lets the oil accumulate while overflowing the hydrosol, so it is easy to collect both in the same batch. Collecting hydrosol (and not re-circulating it back into the boiler) will lower the still’s water level over time so the total possible distillation time will be reduced accordingly. A simple workaround for a long distillation where you want to collect a bunch of hydrosol would be to slowly add water to the boiler as you go.

- Q: How long is each batch?

- A: That is going to vary significantly depending on the type/density of the plant material you distill. In general, fleshy herbs like mint will need very little time before they’re done producing oil; like 45 minutes to 1.5 hours. Slightly woody plants like lavender will require a little more time (2-4 hours). Woody or waxy plants like pine, fir, eucalyptus or spruce needles/branches will need around 6 hours. Aromatic roots like Ginger take around 12 hours. Citrus peels keep (slowly) producing oils for 24+ hours!

- Q: Can Dante be operated outdoors?

- A: Yes with a caveat. There is no reason this still cannot be operated outside in clear weather. However, rain poses an electrocution risk. The controller and electrical connections are water-resistant but should not be left outside or operated in the rain. If the still controller and heating element are brought indoors when not in use, the still itself could remain outside indefinitely as it will not corrode.

- Q: Will you provide instruction/guidance on the setup and operation of the still?

- A: Of course! I am putting together a start-up guide to come with the still and will be available to you by email/phone for any questions.

- Q: Can you ship Dante?

- A: That can be arranged. It would be packed on a pallet and shipped freight/LTL. It would weigh a few hundred lbs. My preference would be an in-person sale so hands-on demonstration is possible but if not, we can work it out with a demonstration video and phone consultation.

- Q: Will you be able to provide replacement parts/service?

- A: Dante is designed to require very little in the way of maintenance or repairs. That said, if any problems do arise, I will be here for you. No foreign call center; you will have the direct number of the guy who built the still.

- Q: Why stainless steel vs. copper?

- A: There are pros and cons to each metal in regards to distillation. It is my opinion that stainless steel is a better choice for ease of use, durability and long-term production.

- Stainless Steel: Very durable. Does not corrode. Does not react with essential oils. Cleans easily with soap and water. The drawback: Essential oils and hydrosols can take up to a few months to age into their “true-to-plant” aroma.

- Copper: Very pretty but a soft metal that is prone to denting and over-heating damage. Corrodes over time, especially when heated and exposed to various chemicals. Difficult to clean; the metal is more porous and usually requires an acid wash to remove corrosion/staining caused by essential oils. Can sometimes change the color of essential oils. The benefit: copper reacts with certain foul-smelling sulfur compounds that naturally occur in an essential oil distillation. The sulfur compounds are deposited on the copper rather than remaining in solution in the essential oil. So the oil comes right out of the still smelling “cleaner” than with a stainless steel still with less or no aging time needed.

- A: There are pros and cons to each metal in regards to distillation. It is my opinion that stainless steel is a better choice for ease of use, durability and long-term production.

Reviews

There are no reviews yet.